The Print 300 Series is built for factories, not just for prototypes.

With its modular platform, rapid chamber extraction, and flexible powder management, it delivers continuous production cycles and safe, automated workflows.

From single to quad-laser setups, the Print 300 Series adapts to your pace of industrialization.

Print Sharp 300

Print Genius 300

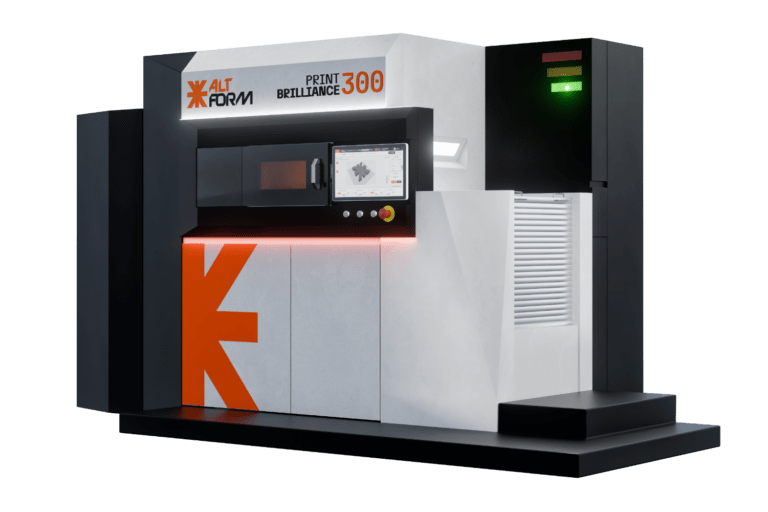

Print Brilliance 300

The Print 300 Series keeps production moving with an automatic chamber extraction system that allows quick removal of the build chamber, so depowdering can take place externally while the machine is already being prepared for the next job. Powder management adapts to different needs, from manual to fully automated closed-loop solutions, ensuring both flexibility and safety.

An advanced filtration unit maintains stable chamber conditions, minimizes gas consumption, and extends filter life through automatic backflushing and built-in passivation.

Combined with an AI-powered Human-Machine Interface, the system offers real-time optimization, predictive maintenance, remote access, and full traceability. This makes the 300 Series more than a machine: it is a connected platform designed for industrial-scale additive manufacturing.

Benefits

- Scalable productivity: from R&D to full-scale manufacturing with 1, 2 or 4 lasers

- Smarter operations: AI assistant, fleet management, and blockchain certification

- Efficient workflows: rapid job changeovers, automated powder handling, minimal gas use

Applications

- Tooling inserts with conformal cooling: optimized molds and dies

- Thermal management components: heat exchangers, cold plates, fluid manifolds

- Aerospace & defense parts: lightweight titanium and aluminum structural elements

Technical Data

- Steel alloys

- Aluminum alloys

- Nickel alloys

- Titanium alloys

- Cobalt-chrome alloys

- Copper alloys

Need something different? Let’s talk about it.

Our solutions can be customized with various laser sources, ranging from more powerful IR lasers (up to 1 kW) to green or blue lasers, as well as mixed-wavelength setups for reflective materials. Our expertise in automation and centralized powder management allows us to design solutions that connect multiple systems, feeding them centrally, recovering unused powders, and streamlining the entire production chain.