We turn advanced laser technologies into industrial reality.

Our expertise spans from the design of high-performance additive manufacturing systems to the creation of fully automated production lines that integrate multiple machines, materials, and processes.

Built on years of experience in laser-based metal manufacturing, our platforms combine precision engineering, intelligent automation, and scalability, empowering industries to move from prototypes to continuous production.

Laser Powder Bed Fusion

AltForm’s Laser Powder Bed Fusion systems are designed for precision, productivity, and process freedom.

We develop scalable solutions ranging from compact research platforms to large, multi-laser production systems: all equipped with open parameters, advanced filtration, and AI-powered human–machine interfaces.

Every system is engineered for automation, connectivity, and consistent performance, enabling seamless integration into industrial workflows.

Whether your goal is prototyping, qualification, or full-scale manufacturing, AltForm’s PBF technology brings efficiency and reliability to every layer you build.

Print 100 Series

Data Sheet

Print Sharp 100

Print Blue 100

Print 200 Series

Data Sheet

Print Sharp 200

Print Genius 200

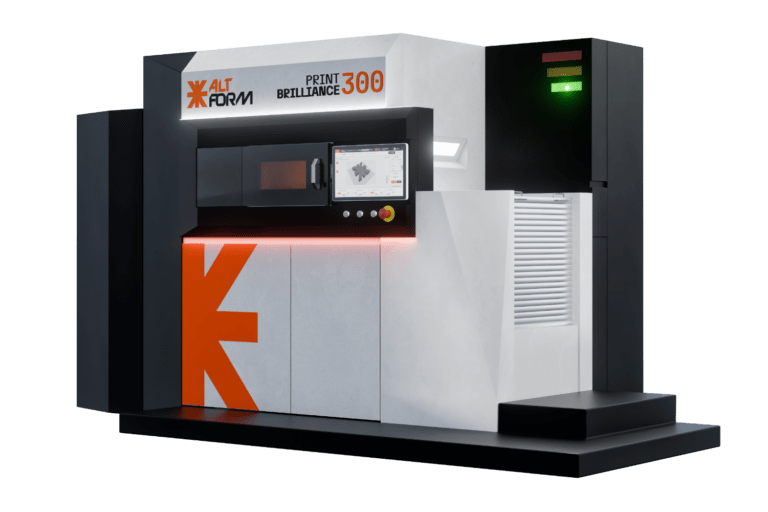

Print 300 Series

Data Sheet

Print Sharp 300

Print Genius 300

Print Brilliance 300

Print 400 Series

Data Sheet

Print Genius 400

Print Brilliance 400

Direct Energy Deposition and Advanced Laser Processes

Our Direct Energy Deposition systems are engineered to build, repair, and customize large metal components using both powder and wire feed technologies.

From high-speed cladding and coating to structural part construction, AltForm delivers flexible and powerful DED solutions that adapt to your production needs.

On the same modular platform, we also integrate Remote Laser Welding, Laser Hardening, and other advanced laser processes, enabling multifunctional cells that expand the possibilities of industrial laser manufacturing.

With in-depth process knowledge, inert atmosphere options, and proprietary laser heads, AltForm systems deliver superior performance, accuracy, and repeatability across materials and applications.

ZENIT Cell

Data Sheet

Single process

Multi process

Inert gas chamber

Rapid Coating Cell

Data Sheet

RC Proto

RC Flex

RC Fast

Beyond machines

Every AltForm solution is more than a system: it’s part of an intelligent ecosystem.

Our AI-powered software supports process optimization, monitoring, and predictive maintenance.

Our materials portfolio includes tested metal powders and consumables tailored to your application.

And our automation expertise allows us to design connected, centralized, and scalable workflows that integrate additive manufacturing and laser processing into the heart of your factory.