AltForm delivers more than high-performance laser and additive manufacturing systems. We provide specialized services for metal additive manufacturing, laser-based production, and industrial automation, supporting companies that want to adopt, optimize or scale these technologies with confidence.

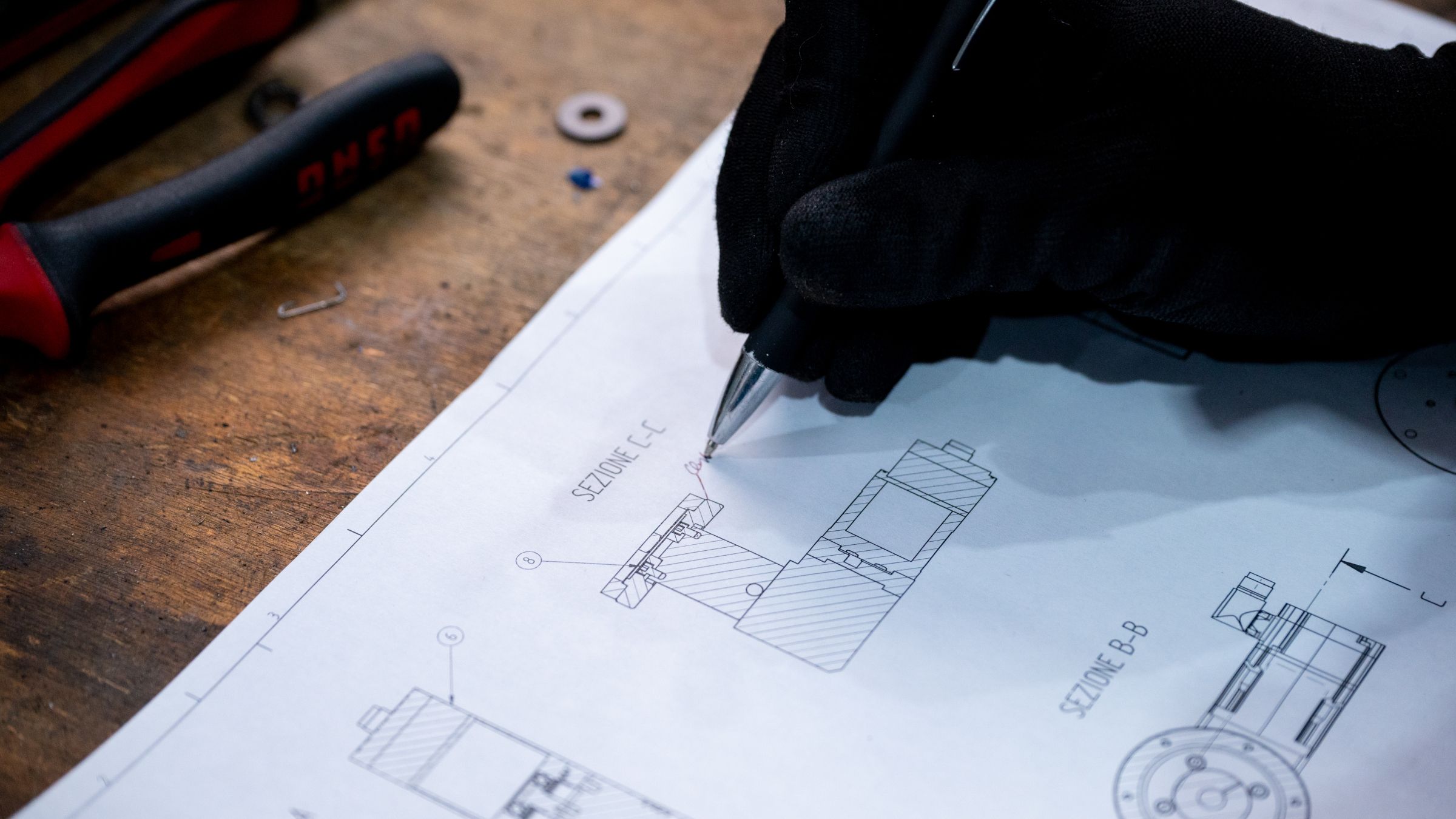

Our engineers help you move from idea to industrial production through structured workflows, data-driven decisions, and hands-on technical support. Whether you are implementing Laser Powder Bed Fusion (PBF), Direct Energy Deposition (DED), or other advanced laser processes, we guide you through every stage: feasibility, design, qualification, automation, and long-term optimization.

Application and process support

Turning ideas into repeatable industrial workflows

Integrating metal additive manufacturing or advanced laser processing requires method, data, and experience.

AltForm’s application engineers work side-by-side with customers to define parameters, validate materials, and build stable processes that fit real production needs.

How we support your success

- Development of stable parameter sets

- Realistic ROI and production strategy

- Complete support from prototype to industrialization

We provide feasibility studies, prototype builds, parameter development, and recommendations for quality control and post-processing. Each project follows a structured path that ensures consistency and repeatability, from the first print to long-term production.

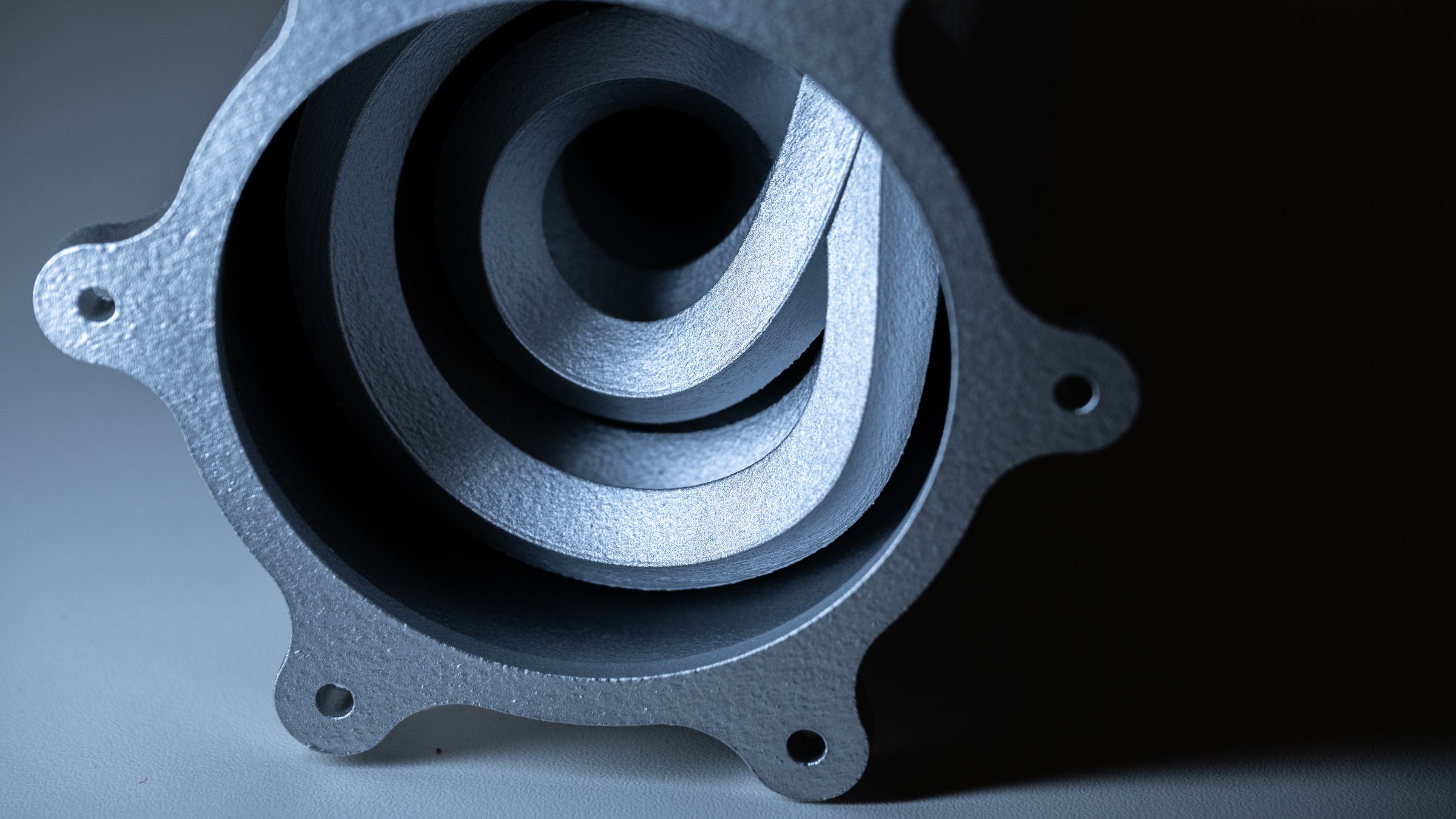

Design for Additive Manufacturing (DfAM)

Engineering parts for performance and efficiency

Design determines whether an additive manufacturing project succeeds. AltForm helps companies redesign components to be lighter, more efficient, and easier to manufacture through PBF or DED.

We work through an integrated approach that includes topology optimization, functional redesign, CAD refinement, and print-strategy definition. The result is a part that performs better, prints more reliably, and is ready for industrial scaling.

Core design capabilities

- Re-engineering for metal AM

- Weight reduction and structural optimization

- Part consolidation to simplify assemblies

Our DfAM support reduces material usage, shortens production cycles and unlocks new design possibilities.

Automation and digital factory integration

Connecting additive and laser technologies with industrial workflows

Scaling production requires more than a machine: it requires a connected, automated environment. AltForm designs automation solutions that integrate PBF systems, DED cells, powder handling, robotics, and digital platforms into one coordinated workflow.

Instead of listing features, this service is best described as a methodology: we analyze your production flow, map the material movement, and develop automation concepts that reduce manual work, improve safety, and stabilize throughput.

Automation highlights

- Closed-loop powder management designed for safety

- Robotic handling for consistent, autonomous part flow

- Integration with MES, ERP, Siemens ecosystems, and OPC-UA

Our digital integration enables real-time monitoring, predictive maintenance, and complete workflow visibility, preparing your factory for high-volume laser manufacturing.

Training and knowledge transfer

Building the skills that make advanced manufacturing work

Effective use of PBF, DED, or laser processing depends on skilled people. AltForm offers structured training programs for operators, engineers and managers who want to master additive manufacturing or advanced laser technologies.

Training is delivered on-site or at our Application & Innovation Center in Turin, where customers can work directly on production systems.

With practical sessions and real application cases, your team gains the confidence to run and optimize production from day one.

Qualification and certification support

Ensuring compliance for regulated industries

Sectors such as aerospace, medical, and energy require strict process and material certification. AltForm guides companies through the path to compliance, from parameter stability to documentation preparation and material characterization.

Instead of overwhelming customers with checklists, we focus on building a certification-ready process: stable, repeatable, and fully documented.

We support qualification toward standards such as ISO/ASTM 52941 and 52942, ISO 9100, ISO 13485, NADCAP, and others.

Our metallurgical partners and testing workflows help ensure part integrity, process repeatability, and regulatory compliance.

Global technical assistance

Service you can rely on, wherever you manufacture

AltForm supports customers through a global service network designed for fast, reliable intervention.

We combine remote diagnostics, predictive maintenance, and on-site expertise to guarantee system uptime. Many issues can be diagnosed and resolved remotely, minimizing disruption to production.

Technical assistance at a glance

- Remote troubleshooting through AI-powered diagnostics

- On-site interventions through certified global partners

- Preventive maintenance plans to avoid unexpected downtimes

We also provide relocation services, calibration and long-term support for spare parts and software updates.

Production scalability support

From pilot projects to industrial throughput

Scaling PBF, DED, or laser-based production requires strategic planning. AltForm helps companies transition from prototypes to serial manufacturing by optimizing cycle times, connecting multiple systems, and designing modular production layouts.

Our scalability support covers cost-per-part modelling, throughput analysis, and hybrid strategies that combine additive and subtractive processes.

We provide clear guidance and actionable data, ensuring that scaling production is realistic, efficient, and economically viable.

Your partner for industrial laser manufacturing

With AltForm, you gain more than a supplier: you gain a partner committed to long-term results.

From early application studies to automated factory lines, our services are built to ensure reliability, safety, and industrial efficiency across every stage of your production journey.